Project Activities

Project Activities

- The construction of a demonstration adobe house to show techniques of earthquake-resistant reinforcement, built in collaboration with El Salvadoran builders. This will be used as a day care centre for young children, allowing their parents to leave their children in a safe environment while they work to support them.

- The production of a presentation, mostly graphic, which will be distributed to the communities of the surrounding area, showing the process of constructing an earthquake-resistant adobe house.

- The collection of information regarding the techniques and processes (both social and practical) of adobe construction.

- The collection of information on the methods of waste disposal and recycling in El Salvador. This information will be used to assist research into possible improvements and in setting up future collaborative projects.

Construction Process

1. Design

Design of the building had been pre-determined to some extent but small modifications were made to the design at each stage of the project in order to best fit the constraints of the site and the requirements of the community. The site for the day care centre construction was donated to the project by Doña Carlos, the wife of a local transportista (truck driver). Details of the various stages of the construction can be seen in the site colour photograph album

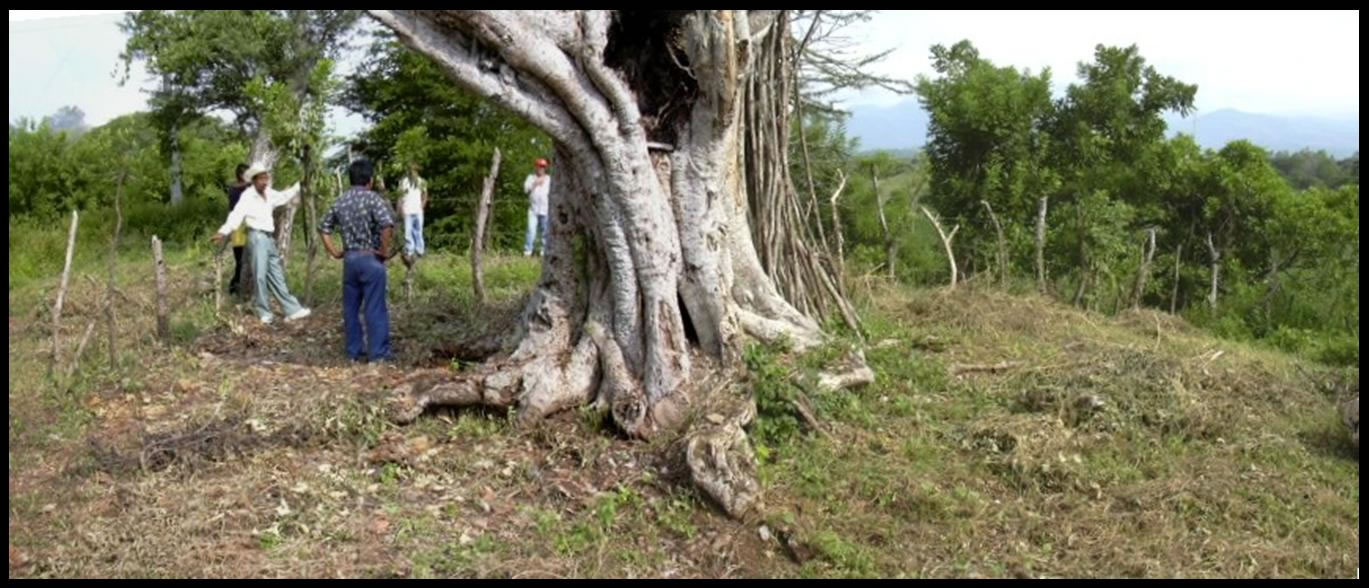

On arrival the site was surveyed and a contour map and cross-sections of the area were drawn. A trial pit was excavated down to the upper rock layer in order to give an idea of the soil stratification.

In constructing in seismic areas it is very important

to obtain a homogenous base of in-situ soil or rock and it was therefore

necessary to excavate rather than cut and fill to obtain a level area.

The project site dropped over 1 metre from one side to the other. The

cross-sections were used to site the building to minimise the extent of

the excavation required. Ground preparation was a considerable task, with

over 30 tonnes of earth being removed from the site – all done by

hand using basic tools. Progress was also hindered by a large dead tree

in the middle of the site (2m diameter) that had to be removed, with all

its root system, during excavation.

3. Adobe

Production and testing of adobe blocks started at the same time as site preparation. Working with Don Adan, our master builder, several mixes were tried using different materials. Initially blocks solely made of local clay and river sand were tested, however the clay content was too high and the blocks cracked during drying. As a result we developed a mix of local soil, river sand and a very fine white pozzolanic soil called ‘tierra blanca’ (literally white earth), which had to be purchased and transported from a nearby excavation site. The new mix worked well and produced acceptable blocks.

Once a successful mix had been defined production started in earnest. The blocks were formed in 30 x 30 x 10 cm steel moulds and were produced in three types: whole blocks, whole blocks with a grove and half blocks. The different types were needed so that the vertical reinforcement could run though the wall and so that buttresses could be provided every 3m to provide lateral reinforcement to the walls. In order to produce and dry the large quantity of blocks required another working site was used. The ground was cleared and a shallow sand layer was spread over the ground so the blocks could be easily moved when dry. The blocks needed to be well covered and protected from the rain and during the early stages of drying, the sun. A network of drainage ditches were dug and tents were constructed with plastic sheeting, wire and timber posts.

4. Foundations and vertical reinforcement

After the building site had been excavated to the lowest point the position of the foundations were set out. The foundations were excavated to the point where they hit bedrock which ranged from a depth of 0.4 to 1.4 m. The entire excavation was carried out by hand as it was important to use as little imported machinery (and operators) as possible to satisfy the goals of the project.

When the foundation excavation was finished the steel rebar was put in place. The rebar consisted of three bar of ½” steel in a triangular arrangement, tied with 3mm steel every 50 cm. A vertical steel bar was connected every 66 cm, taking into account windows and doors, onto which the vertical reinforcement would later be tied. After placing the rebar and a layer of stones the first concrete foundation was poured and cured.

Adobe blocks must be protected from water damage and so the building was designed with a second sobre-cimiento (footing) that would extend above ground level by 30 cm, to raise the level of the blocks above that of surface run-off.

Whilst the construction of the formwork for

the upper foundations was started, 3m vertical bamboo supports were dried

and tied into place using the string lines and a measuring timber to correctly

fix their position. The upper foundations were poured and again wetted

for curing.